June 11, 2022 Saturday at the Movies: Inside Berger and Vihtavuori Remington, Norma Federal, and Hornady Factories. Ever wondered how factory ammunition is made from start to finish. How are brass cases made? How are bullets created? And how are finished cartridges manufactured on automated assembly lines. Today’s video showcase shows six factories that collectively produce bullets, powder and finished ammunition. The Berger Bullet plant is first, followed by Vihtavuori powder manufacturing in Europe. We then show the Remington (now Vista Outdoor), ammo plant from Utah, and a Federal plant that makes rimfire ammunition. Last but not the least, we have a very informative video from Norma’s ammo factory and a Hornady video about their ammo plants.

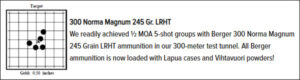

Bullets are being seated at Hornady ammo plant. Recoil TV gives a behind-the scenes look at Berger Bullets and how they are made. Y The video shows the entire process from the raw materials to the placement bullet cores in jackets to the final ultra-consistent, uniform projectiles. To see the complete line of Berger Bullets, with full Ballistic data, visit BergerBullets.comVihtavuori Powder Production in EuropeVihtavuori produces some of the most consistent, high-quality powder on the planet. Vihtavuori powders were used to set world records in many disciplines and win numerous championships. This video shows the European production centers of Vihtavuori. It’s really amazing to see how extruded powder begins with long spaghetti-like strings before being shaped into tiny sticks. This video also shows the entire VV production line. You can see how powder bottles get filled with powder and how the tops are secured by automated machines. This SHWATteam video shows the Remington ammunition plant in Arkansas. Vista Outdoor, which produces Federal, Speer, and CCI ammo has purchased Remington’s ammunition company in Lonoke (Arkansas). This facility, which includes the new high-tech plant at the back, has the equivalent to 13+ football fields (1200+ acres) under its ammo plants, with more than 1100 employees. The production capacity is incredible. This Remington ammunition plant can produce a staggering 7,000,000+ rounds per day when it is at its maximum output. The facility requires a large amount of resources to produce this volume of ammunition. It needs one million pounds of copper per year and 124,000 pounds per day of lead. Although Remington began manufacturing ammunition at the Lonoke facility in 1970 with some of its machines, it has been producing ammo for many years. Norma Factory TourGuys — if you want to see what this site can do today, this video is it. You won’t regret it. Guaranteed. This video is informative and entertaining. This video will show you how cartridge cases are made and should be seen by every serious hand-loader. The editing and camera work are superb. There are many close-ups that reveal key processes like annealing or head-stamping. Norma has released a video that shows how bullet, brass and ammunition are made at the Norma Precision AB factory, which was established in 1902. It is possible to see how cartridges are made. They start with brass disks and then are formed into shape using a series of processes including “hitting [the] cup] with a 30-ton Hammer”. After annealing (shown in 0:08)? Each batch of brass is tested for metal grain structure and hardness. Each case is visually inspected before packing (3:27?). Time-mark

Field & Stream’s reporter recently had the opportunity to tour the Federal ammunition manufacturing facility in Anoka (Minnesota). This large plant produces both centerfire and rimfire ammunition. The reporter was allowed to film the entire process of creating.22 LR ammunition from start to finish while touring the plant. This fascinating video is well worth the effort. This video will show you how rimfire ammunition is made. We recommend that you watch the entire video. This video from Hornady Ammunition Factory will teach you a lot about rimfire ammunition. This video shows how bullet jackets are made from copper and then how a lead core is inserted. The jacket is then sealed over the core, and the bullet takes its final shape in the die (some bullet types have a cannelure). Next, the video shows how cartridge brass forms. It starts with small cups of brass. The final part of the video shows how cartridge brass is formed, starting with small cups of brass. Similar Posts