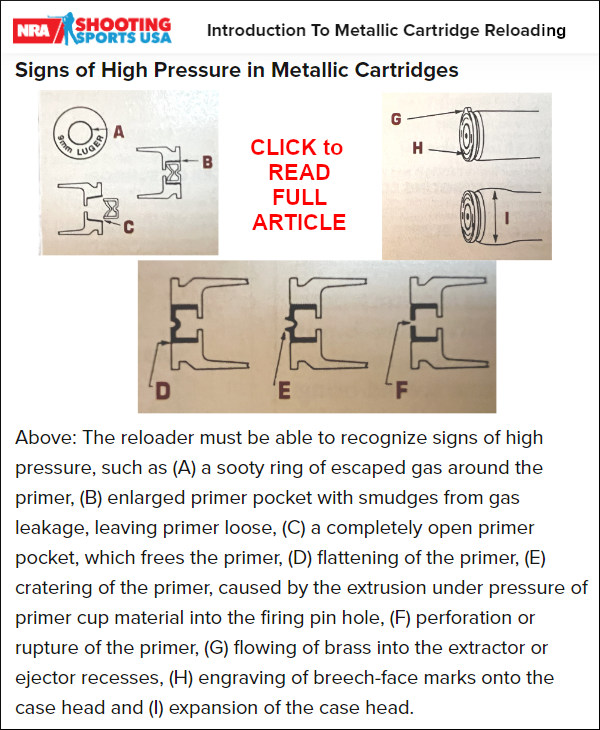

October 4, 2022. Two excellent articles on the basics of metal cartridge reloading are available at Shooting Sports USA’s website. These articles give a great overview of the key steps. If you are new to reloading, we recommend you read both articles:Introduction to Metallic Cartridge Reloading Part II >> Part II is particularly helpful because it explains the entire reloading process step-by-step, with 14 listed steps. The author states that this is the second installment of the series on metallic cartridge reloading. We’ll be following the steps involved in reloading rifle cartridges and refining metallic cartridge loads. These steps assume that you use a single-stage, manual reloading machine and a separate priming device. This article explains the 14 Steps to Reloading. The article explains Step 13: Bullet Seating. It states that it is important to have the proper seating depth. Too much bullet protrusion can cause the cartridge to not work through the magazine or may cause it to stop chambering. Too much bullet protrusion can cause the bullet to intrude too deeply into the powder chamber, decreasing volume, and increasing pressure. It is important to maintain neck tension. Any bullet that fails with some resistance may not seat properly and may be pulled back into the case. This is especially true for semi-automatic arms. “Important Guide for Detecting Over Pressure Signs in Brass

Here’s Part II, which explains how you can determine if your load has exceeded its limit. It is an example of the valuable advice found in these articles. This article should be read at least twice. There are many other things to think about than a stiff bolt lift. Check cartridges carefully. Similar posts:

How Surface Length of a Bullet May Affect Load Force

How Surface Length of Bullet Bearings May Affect Load Pressure on March 18, 2025Photo 1: Three 7mm bullets with different shapes and sizes that are nearly equal in weight (