October 30, 2022Evergreen ballistics — Vendor of Coated, Cast, and Plated BulletsEvergreen is a shooter-owned business that sells a wide range of coated lead bullets, cast bullets, and copper-plated bullets. Evergreen Ballistics offers a wide range of cast and/or plate bullets for your rifles and pistols. The prices are very affordable and the customer service is outstanding. Evergreen Ballistics was founded in April 2020. Soon, the company was asked by many customers to produce coated bullets. Marc McAtee, the owner of Evergreen Ballistics began to work: “I ordered several colors of Hi-Tek Supercoat [to] test.” The line of coated bullets was launched in mid-2020. They quickly became our most popular type of bullets. Evergreen launched a line EB-branded plated pistol cartridges made by a major North American plated bullet manufacturer a year later. “I have always tried my best to keep Evergreen Ballistics’ mission focused and simple. We offer high quality projectiles for reloaders at the most affordable price. We treat our customers the same way we would like to be treated. We do our best to be fair to customers, whether it’s fast and inexpensive shipping or answering every email. Marc McAtee, Evergreen BallisticsEvergreen Ballistics Polymer Coated Bullets

Evergreen Ballistics offers two types of coated bullets: 1) NLG, or “no-lube groove” bullets; 2) grooved bullets made with the same alloy and molds that its regular cast lead bullets. NLG bullet molds were created to meet the increasing demand for coated bullets. McAtee explains how the coating works: “After cooling and casting, the bullets are weighed onto individual wire trays. The coating is then mixed in with a solvent (in our case, acetone) and applied to the bullets. The coating is applied by shaking the bullets vigorously in a large bowl. The bullets are then laid out on wire trays to dry completely. The coating is then set by backing the bullets for approximately 10 minutes. Two tests are performed to confirm the integrity of the coating after it has cooled. This shows that the coating is cured. Next, we smash a bullet using a hammer. The coating should not fall off. This is a sign that the coating has been chemically bonded to lead. These tests are done on every tray that comes out our ovens. The second coat is then applied. After the bullets have cooled from the second coat, they can be sized using carbide sizing tools. To aid in the sizing of the bullets, we use a small amount fluoropolymer-based oil lubricant. One of the most common questions I receive is “Does the coating come off during the sizing?” It does not. It will stay on the bullet if the coating has been properly cured. It will stay on the bullet just like it does when it travels down the barrel. The coating is Hi-Tek Supercoat, manufactured by J & M Specialized Products Australia. This polymer coating offers many advantages. The coating reduces barrel leading by nearly eliminating it. The coating also means that there is no greasy lube that can vaporize and significantly reduces smoke. Evergreen Ballistics Cast Lead Bullets

Evergreen Ballistics offers a complete line of conventional lead bullets in addition to its green-coated bullets. They are made from an alloy of 92% lead and 6% Antimony. This alloy is capable of producing good performance at a variety of velocities. Marc McAtee says: “Our molds were designed with the high-quality alloy in view. Our lead arrives clean so we don’t have to do any fluxing and there is not much dross to remove from the pot. Our lead bullets have been sized using machined carbide tools and lubricated with Commercial 160 from White Label Lube Company.

Evergreen Ballistics Plated Bullets

A leading North American bullet manufacturer produces our plated bullets. To ensure a consistent starting weight, the lead cores are weighed. The cores are then electroplated, which deposits a copper layer that completely encapsulates it. This copper layer is approximately 0.08? The copper layer is approximately 0.008? in thickness. The bullets are then resized in order to maintain concentricity. These bullets are plated with heavy metal to allow them to be pushed at higher velocity using FMJ load data. Interview with Marc McAtee founder of Evergreen BulletsQ. What inspired you to start Evergreen BulletsQ?

A: I was inspired to start the business in 2018 when I found a commercial casting setup at an estate sale. I purchased the automated casting and sizing equipment, as well as a selection of molds. To optimize the production process, I would cast and melt many batches of lead bullets over the next few months. In April 2020, Evergreen Ballistics was established and I began selling cast bullets online. I started using Hi-Tek Supercoat to coat small quantities of lead bullets and began making polymer-coated bullets myself. Customers asked me shortly after I discovered about the Supercoat product if we could make coated lead bullets. Q. After trying out many coatings and ratios, I finally settled on the one we use. What are the advantages of polymer bullet coatings

A. A. Cast bullet lube is not present on your reloading tools. Polymer coated bullets are easier to shoot and easier to load than plain lead bullets.

Q. Q.

A. Our coated bullets use the same 92/6/2 aluminum alloy as our cast-lead bullets. This ensures that the cast weights are consistent. Some coated bullet companies have moved to a 98/2 alloy. Although it’s cheaper, the weights are not the same. OUR plated bullets have a plating of 0.008? thick. Other plated bullets are available in a range of 0.002-0.006? In plating thickness. Q. Q. How are jacketed bullets manufactured?

A: We are able to disclose that our jacketed bullets were not manufactured in-house. They are made by a contractor. The cores of the plated bullets are made from chucks of 98% and 2% lead wire. The cores are then shaped into the rough bullet shape and sent to the plating process. This involves several steps in different chemical baths. This results in strong adhesion between the copper plate and the lead core. The bullets are then formed in a hydraulic press to ensure consistent dimensions and consistency between bullets. Finally, the bullets will be polished and shipped in 50,000-piece boxes. After being received from the contractor, several bullets are tested for consistency in weight and dimension. Q. Is it possible to keep up with high bullet demand?

We are a small business and do not have large OEM or wholesale customers. All the bullets that we make and sell go directly to reloaders. During the last major rush for ammunition/bullets, this was evident. We were able ship orders in less time than expected, whereas some manufacturers took 4-6 weeks to ship orders. We didn’t get stuck with huge OEM bullet orders. All of our capacity is used to support everyday reloaders.Q. Q. Will there be any new calibers/bullet type in the near future.

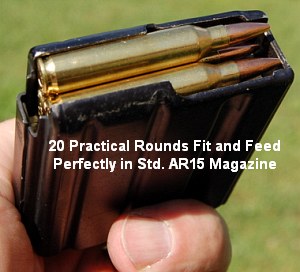

Our newest additions to our plated bullet range are our.458 diameter ammunition. These bullets come in a 300gr or 405gr RNFP, as well as a Spitzer design that is available in 350gr (450gr), and 500gr sizes. We are currently developing a coated bullet of 220gr.308 caliber for the suppressed 300 BLK crowd.

Similar Posts