November 6, 2022.375 and 0.408 CheyTac brass for ELR from Peterson Cartridge. You will need a large-caliber cartridge that has plenty of boiler space. The CheyTac family has been the basis of some of the most successful ELR cartridges, including the.375 CheyTac (9.36×777) and the.408 CheyTac (10.36×777). Peterson Cartridge offers brass for both of these jumbo cartridges. The Peterson Cheytac brass is durable and long-lasting. It is also capable of winning. Derek Rodgers won 2017 King of 2 Miles (K02M), shooting a.375 Cheytac using Peterson brass. Here’s a report about how Peterson developed its tough CheyTac cartridge brass.

Derek Peterson, our president, has tested the latest iteration.375 CheyTac, also known as 9.5 X77. He started with five casings and did a full body resizing after each firing. He fired 17 firings from each casing before he noticed the first signs of case head separation. These were loaded with very high pressure loads. He then took another set and just bumped his shoulder back after each firing, as a typical reloader would. He fired 20 times with those casings.

Note: CheyTac (R) is a trademark registered by CheyTac USA LLC. Peterson Cartridge is not affiliated.

The muzzle velocity was within 12 feet per second for the first two shots. The muzzle velocities of the 3rd and fourth shots were within 6 feet per se. The muzzle velocity was within 1 foot per second by the 5th shot. This is how two bullets can be placed in the same hole at the same time.

These calibers don’t have a SAAMI spec, as many of you know. There is no SAAMI spec that specifies the maximum pressure at which a service load can be applied. There is an international spec for the.408 that has been promulgated by CIP (Commission International Permanente). The CIP maximum pressure for this round was extremely high. Our European partner tells us that it is probably unnecessary high. These rounds were loaded by our partner in Europe. They also have a standard load for.375s, which is quite high. That was the pressure we tested at. We had to use a compressed load in order to achieve this pressure. This is to explain that you shouldn’t use a hot load and that you will probably get more reloads than us. Peterson Brass passes 11 dimensional tests

We perform a series of real-time, in-process dimensional checks on all casings made in any caliber. We test 11 dimensions every shift. These include tube cylindricity and mouth to body concentration, primer pocket diameter, length from shoulder, overall length, and many others. These measurements are automatically input into Statistical Process Control software. These measurements are automatically fed into Statistical Process Control software.

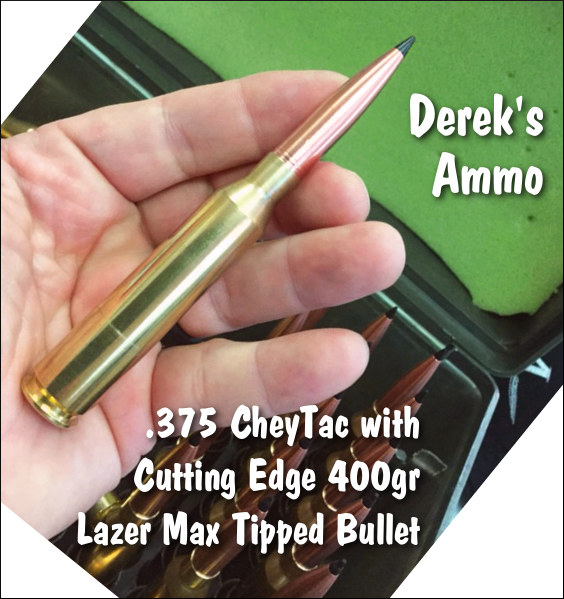

Peterson Cartridge bought additional manufacturing equipment specifically designed to produce large casings. We can produce 5-million casings per year. We are committed to ensuring that there is never again a shortage in these calibers..375 CheyTac — World-Beating Cartridge Derek Rodgers is 2017 King of 2 Miles. He is also the first human to reach the maximum distance target of 3368 yards (1.91 mile) in competition. His choice of cartridge? The.375 CheyTac. Derek ran Cutting Edge Bullets using Peterson brass and Hodgdon H50BMG Powder. Q: Why did the.375 CheyTac cartridge get you interested? Derek: I was asked to join Applied Ballistics Team and needed an ELR rifle made in a very short time. To complete the project, I had to work under very tight deadlines. To eliminate any variables, I tried to keep the project as simple and standard as possible. The.375 CheyTac was chosen for its ease of accessing components. It is more difficult to find components quickly with larger rifles, so I felt the.375 CheyTac had enough characteristics to be competitive at ELR distances. EdLongrange Product Tip We welcome submissions from readers.