Do you use bushings when sizing your case-necks? Do you assume that your bushings have a hole centered in the middle and are round on the inside? You may be in store for a nasty surprise, as our friend Jim de Cort discovered recently. Jim was worried about the run-out of his brass. Jim’s cases went straight into his bushing-equipped FL Die, but came out with a run-out of up to.004″‘. Jim asked, “What’s going on?” “Could it be the bushings themselves?” asked Jim.

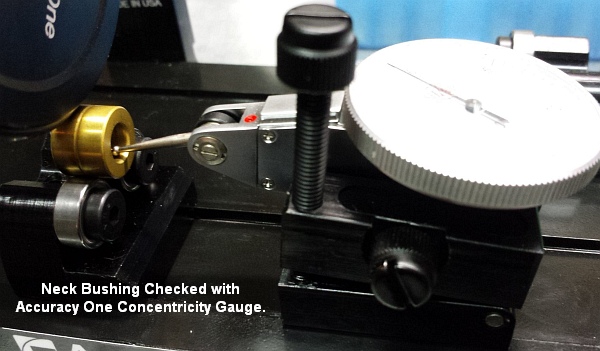

Jim decided to check his bushings in order to answer this question. Jim checked his neck bushings using an Accuracy One Wheel Drive concentricity Gauge. What he found may surprise you…

Neck Bushing Flaws are Revealed

Jim de Kort: Trust no one!

Jim writes: “I tested the concentricity and accuracy of my 6BR round today. I measured the concentricity of my 6BR rounds today. It appears that the bushing was to blame. The bushing was the culprit.

One bushing was crooked because it had a.00025″ deviation on the outside and a.003″ deviation on the inside. Even when I use a bushing within.001″ of the size I need,.003″ runout is still present after sizing. I repeated the procedure for my 6×47 with the same results. “When using the bushings, concentricity is affected a lot.”

Before we blame bushing makers, we need to acknowledge that there are many factors that can cause excessive run-out or misalignment of the case-necks. Jim is the first to admit that we don’t know the answer. These are still interesting results, and they give precision hand-loaders a lot to think about.

Jim Borden, of Borden Accuracy, also offers this tip: “Check the trueness the face of die cap. This has more to do than the bushing with trueness. Check the perpendicularity between the hole in the bushing and top surface. When I was making dies the cap was made by threading the threaded tenon and facing it in the same setup.”

Editor’s Comment : Jim is not the only one who has had some strange results. I use honed non-bushing chambering dies. These non-bushing honed dies (with necks honed to.002-.003″ neck tension) produce ammo with run-out consistently below.0015″.