August 6, 2021

The AR15 semi-auto rifle is America’s favorite semiauto rifle. It is accurate, modular, and extremely versatile. The AR is a maintenance hog, but let’s face the facts. The AR’s gas tube blows carbon, soot and other particles right into the bolt assembly, where they cake on the metal. There are many small parts and recesses in the AR bolt that must be cleaned regularly. The reason ARs have failed is often gunk (dried oil, carbon, or brass shavings) in their extractor spring recess.

An AR that is clean is a happy AR. There are many schools of thought about how to maintain an AR. Some people prefer to run their AR “dry”, with minimal lubrication on the lugs or friction surfaces. Others prefer to keep their ARs “wet” with lots of lube. No matter what your preference, your AR must be cleaned regularly. The AR’s bolt/carrier is the most important part of the AR. The AR-15 bolt/carrier is the most important part of the AR-15, as it is involved with feeding, firing, extracting, and so on.

Bolt Take-Down Guide at Top Quark Blog

Top Quark Blog editor has created an excellent AR15 Bolt Take Down Guide that shows you how to disassemble an AR15 carrier and bolt for regular cleaning. Even if your AR15 shooting skills are not the best, this page (sample below) can still be helpful. You may also want to bookmark it for future reference. The photos are large and clear, and there are helpful hints for each stage.

The author is an expert and shares valuable insights. He notes, for example, that the extractor springs in most AR15 bolt assemblies can be quite weak, which can lead to many extraction-related failures. Colt assemblies have a few positive points. They use stronger extractor springs. The inner plastic insert can be used to tell the difference. Colt strong springs are made with a black plastic insert. Normal springs have a blue insert.

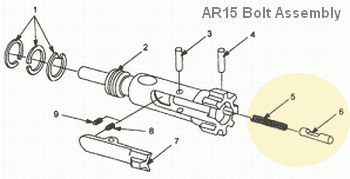

One thing is missing from this page: the author doesn’t cover cleaning and disassembly of the ejector assembly. This is very important. It is possible to cause malfunctions by adding small brass shavings and carbon and lube into the ejector slots. When this editor is called to diagnose problem ars, the first thing I look at (after reading magazines) are the ejector recess as well as the slot for the extractor. Ejector jams and failure-to-eject are often caused by clogged ejectors. It is important to keep the ejector hole clear. You will have problems if you leave greasy lube residues, along with tiny brass shavings and carbon, in the ejector hole. It is easy to remove the ejector (#6), ejector spring, (#5) by simply drifting the ejector pin (#4).

NOTE: The original Quark Blog Article appears offline (see Quark LINK.). This excellent article has been saved via the WayBack Machine Internet Archives. CLICK HERE to view the Full Quark Blog Article via WayBack Machine Archive

Similar Posts

Tags: AR, AR Maintenance. AR15. Bolt, Disassembly. Spring. Top Quark. WayBack Machine.