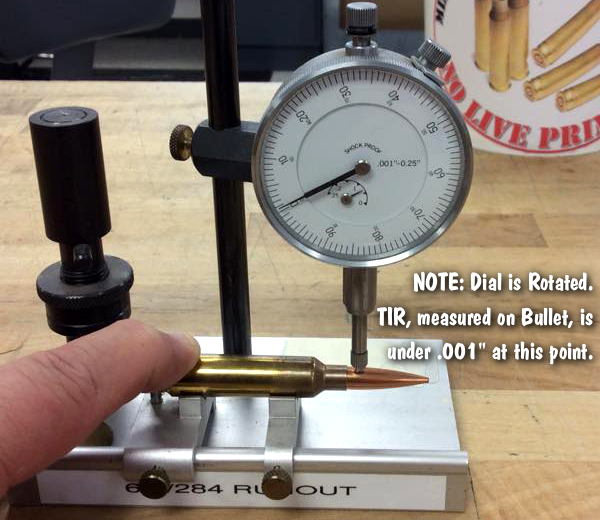

October 10, 2021. The U.S. Army Marksmanship Unit publishes regular reloading “how to” articles on its USAMU Facebook page. This USAMU article, which is the second in a series of articles on improving concentricity has many useful tips. This article is worth reading if you use standard (nonmicrometer) seating dens when loading certain cartridge types. For more tips on handloading and marksmanship, visit the USAMU Facebook Page. It’s time again for USAMU’s Handloading Hump Day! Last week, we discussed how to achieve very high loaded-cartridge concentration (AKA “TIR” or Total Indicator Readout) with standard, “hunting-grade” reloading tools. We showed you how to set the Full-Length size die to float slightly, once it is adjusted for your case headspace. We also mentioned a study that showed this method loaded ammunition straighter then a set [higher-grade] match dies from a similar maker. To allow the die to float slightly, a rubber Oring was used below the locking ring. This helped reduce TIR. READ Full-Length Sizing Die TIP HERE.] To minimize TIR, we’ll now set up a standard-seat die. This is the other half of our two-die system. We’ll continue to use a single-stage presses as most handloaders will already have one. For consistent and accurate results, a high-quality runout gauge will be essential. After you have sized, primed, and charged your brass, it is time to move on to bullet seating. There are many options, but this is the best. To set up a standard seating machine, place a trimmed, sized case in the shell-holder. Next, raise the press ram to full height. Next, remove the seating stem and screw the die down until it touches the case mouth. To prevent cartridge crimping, turn the die one-quarter turn beyond this setting. Next, lower your press ram and take out the case. Place a flat steel piece on the shellholder, and then raise the ram. The flat steel should be placed on the shellholder to tension the die bottom. This will help center the die in the press threads. You can check this by gently moving your die until it is centered. Secure the die lock ring by keeping the die under light tension using the press ram. If you are using a micrometer-type seat die, the next step is to insert a loaded case with a bullet into the die. Screw the stem down to get the correct cartridge OAL. Standard dies may require an additional step. If the die has a loosely-threaded seat stem, adjust the seating depth, but don’t tighten its lock nut. To center the seating stem, place a loaded cartridge fully in the die. Secure the stem’s locknut. Next, load the sample cartridges and verify that they are concentricity. You can also try different methods, such as allowing the seating stem to float slightly in order to center itself in the die. However, you must maintain the correct OAL. Any changes in concentricity will be shown by the runout gauge. The first method produced excellent results, as demonstrated by the previously mentioned experiment. These results (TIR Study 2: Standard vs. Custom) will be reproduced below for your convenience. TIR Study 2 – Standard vs. Match Seating Dies 50 rds. of.308 Match Ammo loaded with carefully-adjusted Standard dies, vs. 50 loaded with expensive “Match” dies from the exact same manufacturer. Standard dies, TIR:

0.000″ – 0.001″ = 52%

0.001″-0.002″ = 40

0.002″-0.003″ = 8. None less than 0.003. “Match” dies, TIR:

0.000″-0.001″ = 46%

0.001″ – 0.002″ = 30

0.002″ – 0.003″ = 20

0.003″ – 0.004″ = 4. AccurateShooter Comment : This shows that the standard dies are as good or better than the “Match” Dies. These tips will help shooters get the best out of standard loading dies that are inexpensive. If you are using cases that have been fired in a concentric chamber as described above, high-quality match dies or brass can produce ammo with almost no runout if you handload carefully.

Similar Posts: Tags : Bullet Seating. Concentricity. Improve Concentricity. Runout. Seating Dies. TIR. USAMU