November 7, 2021 Annealing Made Perfect, (AMP) — Technical Overview Annealing Made Perfect, a New Zealand-based company first revealed its induction annealing machine, at SHOT Show 2015. It was huge news in the reloading industry. This was a breakthrough: an induction annealer that ran on electricity was fully programmeable. There were no more flames to worry about. The AMP annealer was a game-changer for shooting enthusiasts who reloaded ammo. Smart science and modern technology are the foundations of the AMP system. AMP invested in the latest lab equipment right from the beginning, such as gear for Micro-Vickers Hardness Testing. AMP also collaborated with outside metallurgical labs. AMP also invited shooters from all over the globe to send in samples of cartridge cases. AMP accumulated a large archive of cartridges, ranging from.17 Hornets to a variety of.50 BMG wildcats, and everything in between. AMP’s archive contains multiple brands and different lot numbers of the exact same cartridge. AMP offers the most advanced and precise consumer annealing systems on the planet. This is due to the incredible amount of R&D behind the product and the use of advanced technologies. Annealing Under the Microscope — Informative articles Alex and Matt Findlay created a series of articles called “Annealing Under the Microscope”. The first of these articles was published in July 2017. Part 1 was a general explanation about annealing and dispelled a few myths. It examined the repeatability and reliability of annealing with multiple reloads and performed a series bullet pull tests. FULL ARTICLE LIKE: Annealing under the Microscope, Part 1 Annealing Different Brands of Brass

Part 2 of Annealing Under the Microscope covered a very important topic: annealing for different types of brass. This article explains why different cartridge brands may require different annealing settings. It is also revealed that annealing settings can be different for brass from different brands. FULL ARTICLE LIKE: Annealing Different Brands for the Same Cartridge Type AZTEC Annealing System — Smart Machines are made by AMP Annealers

Alex and Matt began the development of their revolutionary AZTEC technology in late 2017. This system transformed AMP annealers from SMART annealers. This allowed customers to analyse their cases with laboratory-grade accuracy without having to send samples to the AMP laboratory for calibration. After nearly 12 months of research on AZTEC, Part 3 of Annealing Under the Microscope came out in July 2018. It addressed how to best use this self-calibration capability. It also highlighted the differences between brass brands that are “premium” and those that are cheaper.

FULL ARTICLE LINK AZTEC Control – “Smart” Self Calibration Annealing Technology Benefits from Precision Annealing — Accuracy, Repeatability

September 2019 saw the release of Part 4. It covered the true benefits of accurate Annealing and the arguments for analyzing every reload. The key factors in the study were repeatability and accuracy in sizing. This article also showed the first prototype of AMP’s new auto bullet seater. It also included seating pressure data capture. FULL ARTICLE LISTE: Benefits from Precision Annealing — Accuracy, Repeatability Proof on Target — Down-Range Advantages of Annealing

Part 5 of the series features AMP’s experts focusing on the real-world, down-range benefits. This was a more complicated process than AMP originally planned. Part 5 was therefore conducted in three stages with three detailed write ups. Part 5 Stage 1 examined the accuracy of annealed and un-annealed cases. It used three sets of identical Peterson Cartridge.308 Winchester cases and twenty (20) reloading cycles. Each cycle saw cases being measured fire-formed as well as re-sized. Each cycle was measured for its length, shoulder bump and neck OD. FULL ARTICLE LIKE: Annealed and Un-Annealed: 20 Load cycles with.308 Winfield Testing in Tennessee — Proof on Target

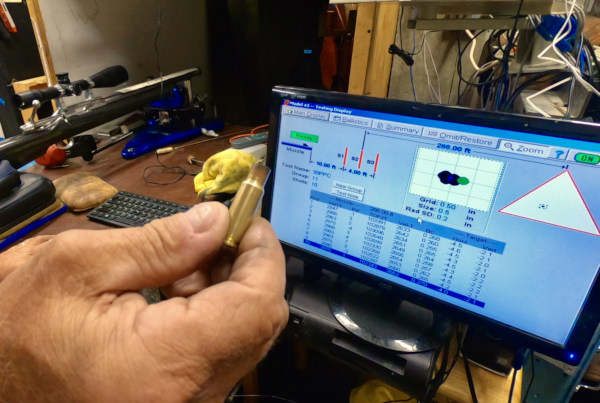

Part 5 Stage 2 covered detailed ballistic testing with multiple rifles, cartridges and shooters at the Strategic Edge range, Tennessee. The Tennessee testing sessions collected a wealth data on velocity spreads, group sizes and distances up to 1,000 yards. The evidence demonstrated a clear advantage for annealed Brass, both in terms of average group size and Extreme Spread for groups shot with AMP annealed cases. FULL ARTICLE LIMIT: AMP Annealing Tennessee Long Range Testing Underground Testing with Lou Murdica

AMP’s Part 5, Stage 3 paper featured Lou Murdica testing at an underground range in California. We previously showed a video in which Lou shot one case, then reloaded it and shot the same case into the same hole at 100 meters. He repeated the feat again, shooting the same un-annealed case twenty more times into the same hole. Lou then produced another 20-shot group using a case he had annealed before each shot. FULL ARTICLE LINK AMP Annealing Underground Test Enjoy These Technical Articles From AMP Annealing

Collectively, AMP’s “Annealing Under the Microscope” series is a remarkable collection of outstanding work. This series of informative articles will help you learn more about annealing cartridge brass. Similar Posts: Tags: AMP Annealer, Amp Annealing, AMP Press, Annealing Made Perfect, Lapua Brass, Lou Murdica, Norma Brass