November 11, 2022

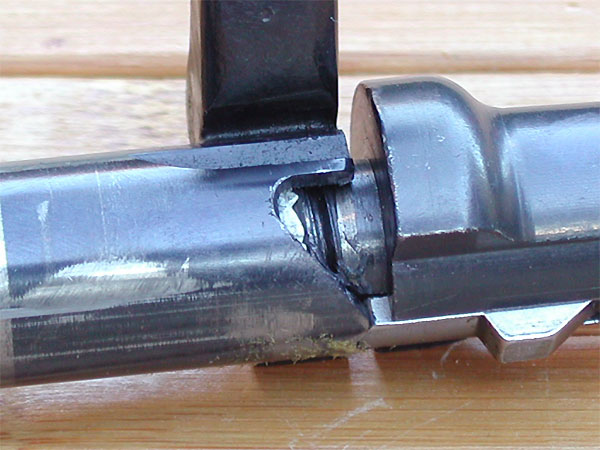

From top to bottom: Remington firing pin assembly, Tubb SpeedLock allot-composite system with ISS, Remington short-action firing pin assembly, and Tubb SpeedLock without ISS (current versions have dual-wound springs) One informative USAMU article dealt with mechanical issues and related ignition irregularities which can cause vertical fliers, even with excellent ammunition. This article contains some useful tech tips. Poor or inconsistent ignition is a common problem when dealing with vertical fliers that are not supposed to exist. It is possible to avoid frustration and time-consuming loading by being familiar with the basics and knowing what to look for. Bedding, crown, and scope/sight mountings are all important. If they are, then you might check for ignition issues before embarking on an expensive, futile and possibly unsuccessful quest for the “magic handload”. If they are, you should check for ignition problems before embarking on an expensive, futile, and possibly futile quest for the “magic handsload”. It produced consistent “bugholes” groups at 50 yards with one lot of ELEY Tenex. However, similar groups were destroyed by a different lot of Tenex. These vertical fliers are not found in other rifles. Instead of spending days searching for “magic lots” in expensive ammunition, he called a respected rimfire gunsmith. He quickly examined the rifle’s actions and found the culprit. The firing pin spring was weak and a chip from the firing pin’s face where it touched the cartridge rim were the culprits. After tuning the parts, the rifle began shooting small, bughole groups of Tenex. A positive, consistent ignition can also be beneficial for centerfire rifles. A wise riflesmith is worth his weight in gold! Ask your club if the Remington 70, Winchester 70, Springfield-based match-bolt gun you are using still has its original 40-80-year-old factory striker spring. A replacement spring is cheap insurance against future or current problems. It might be a good idea to keep to the factory-spec spring weight. A strong spring can cause vertical just like a weak one. Routine inspection for firing-pin protrusion can be a quick way to rule out potential problems. This is becoming less common with precision-machined custom actions. Below is the firing-pin assembly for a custom BAT operation. Is the tip out-of-center in the hole? If so, it could be striking it as it goes forward. Is the hole out of round or a result of repeated strikes? A trip to the riflesmith may be necessary if the hole is out-of-round or burred from repeated strikes. These issues are rare in high-quality rifles, but they can still happen. It takes only minutes to diagnose them. It might be worth removing the cocking/firing pin/spring assembly to check for unusual gouges and dings. This is one reason these tried-and-true methods have a loyal following among hunters who must keep their rifles in the field. Both the firing pin assembly as well as the bolt need to be cleaned. This can improve the firing pin speed and consistency. Other bolt-action designs may require a take-down tool, or other measures. After ensuring that the rifle is unloaded, slowly cock it, dry-fire, then repeat several times. Pay attention to the sound it makes. Is the striker falling making the same sound every time? Do you feel or hear the striker falling making a grinding sound upon operation? Do you feel or hear grinding? Similar to the examination for abnormal wear marks, you should look out for signs of roughness or a need for light polishing. Next, clean and lightly grease bearing surfaces.

These are simple checks that shooters can perform on their own to conduct a preliminary inspection. Other mechanical issues can also lead to ignition problems, primarily centered around the trigger, sear, and spring. It is a good idea to take these issues to a qualified riflesmith who is experienced and qualified. We hope you find the following information useful. We hope to see you next week! In the meantime, have fun shooting safely!

Similar Posts