August 17th, 2021

These are two bullet types that were seated at the same CBTO length but with different COAL. The comparator tool left shiny scratches on the bullets. This indicates that there is a point on the bullet ogive where the ogive will engage with the rifling.

Bryan Litz, Berger Bullets

Part 1 of this series focused upon the importance of COAL in terms SAAMI standards, magazine lengths and seating depths as well as pressure levels. Cartridge Base to Bullet Ogive Length is another important measure of loaded ammunition’s length.

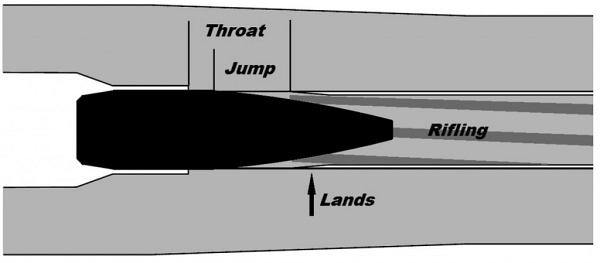

Figure 2. Figure 2.

Figure 2. Figure 2. This configuration of bullet seating is called touching the lands or touching the rifle riflings. It is an important measurement for precision hand-loading. Because of the complex dynamics of internal ballistics, which can happen in a blink of an eye and the speed at which a bullet moves out from the case before it engages with the riflings, precision potential is extremely important. To optimize precision in handloading, it is crucial that precision hand-loaders understand how to adjust the bullet seating depth relative to the barrel rifling. Understanding how to measure the Cartridge Base To Ogive dimension (CBTO), is a key part of this knowledge. This is covered in the FULL ARTICLE.

Bryan Litz provides a detailed discussion on measuring CBTO with various tools and methods, including Hornady OAL gauge. This discussion can be found in the complete article on the Berger Bullets site. Click Here to View the Full Article

Why not use CBTO as a SAAMI Standard instead?

CBTO is an important component of rifle accuracy. You might wonder, “Why isn’t it listed as the SAAMI standard, along with COAL?” It is not listed in the standard for one reason. This is due to the lack of uniformity between bullet nose shapes and measuring devices used for CBTO determination.

Benefits of a Uniform CBTO

When checking your COAL, there is an additional aspect to knowing your CBTO. This is related to performance. You can achieve a CBTO that is less than +/- 0.001 with good bullets, tooling and well-prepared cases. But your COAL can vary up to.025 Extreme spread (or more with different brands). This isn’t necessarily bad, and it is better than the opposite. If your CBTO dimension is variable but your COAL dimension tight (within +/–.002? It is possible that your bullet is settling inside the seater cone at the bullet tip. This is a very serious problem and should be avoided. It is not unusual for bullets with identical nose shapes to differ from one another. However, it is also common for bullets with the same nose shape to have different nose lengths.

Summary of Cartridge Base to Ogive (CBTO), Discussion

Here are four important considerations when it comes to bullet seating depth and CBTO.

1. CBTO is an important measurement for handloaders, as it directly relates to precision potential. You can control it by setting the bullet seating depth.

2. There are many tools and methods to measure CBTO. There are many pitfalls in measuring CBTO, which can lead to inconsistent results. This is something you need to be aware of before you start.

3. A CBTO that produces precision in your rifle might not be the best in another’s rifle. Even if you have identical rifles, bullets, and models of comparator gauges, it is possible for the CBTO to produce different results. It is possible that the gauges may not be the same. The measurements from one gauge might not translate to the same dimension from another.

4. When producing high-quality handloads, it is important to ensure that the CBTO you choose produces the most precision in your rifle. This can be achieved by using high-quality bullets, tooling, as well as properly preparing case necks and mouths for consistent seating.

CLICK HERE for the complete article with more information

Sourced by EdLongrange We welcome suggestions from readers.

Similar Posts

Tags: Bullet Seating, Reloading, Bryan Litz. Bullet Ogive.