December 10, 2021 Four Ammo Safety Inspections to Perform Every Time Before You Shoot Here’s a helpful article by Carroll Pilant, Sierra Bullets Media Relations Manager. This story originally appeared on the Sierra Bullets Blog. It covers some of the most common ammo problems faced by hand-loaders. These issues include excessive OAL, high primers and incorrectly-sized cases. Here is Mr. Pilant explaining how to avoid common problems that can lead to “headaches on the range.” I had some gentlemen come to my house last fall to get rifle zeros for an upcoming hunt with the elk. One man was using a.300 short mag and each 3rd or fourth round wouldn’t chamber. The bulge was found at the body/shoulder junction. These were brand new cases that he had brought on the trip. The seating die was lowered to just touch the shoulder, and then slightly backed up. Some cases were slightly longer than the datum line, and the shoulder was hitting the seating die, putting the bulge onto the shoulder. I was struck by the number of gun malfunctions I see at matches each week. The majority are caused by poor handloading techniques. One: Use a Chamber Gage to Check Your Cases. I shoot a lot in 3-gun matches. I often see AR problems that result in the shooter banging on the buttstock or closest solid object while simultaneously pulling on the charging handle. I don’t like it when people treat my rifles that way. It makes me cringe everytime I see them do that. I often ask them if they run the ammo through the chamber gage. They usually reply, “No, but we need one” or “I don’t have the time” or some other excuse. It can make the difference between a nightmare or a smooth-running firearm. The Chamber Gauge quickly reveals long or short cases

Size your cases correctly

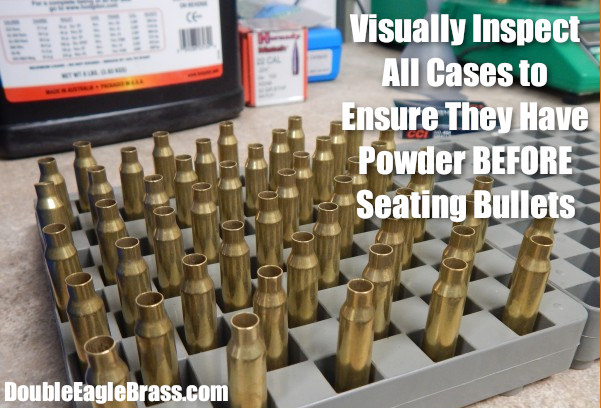

Sizing the case can also be a problem. The expander ball will be easier to remove if you lubricate the neck. The expander ball will make a loud squeak when it comes out of the case neck. Sometimes, this is a matter of pulling the neck/shoulder up several thousandths. This is enough to make sure that the bullet doesn’t jam into the chamber like an old cork if there isn’t a bulge at the shoulder. The rifle will not fire if it is correctly set up. However, if the round is stuck in the chamber, it will not go into battery. This could have been detected by a chamber gage. The firing pin is not long enough to reach the primer solidly enough to ignite the case 100% of the times when cases are over-sized. If you have one that is too large, you will have several. This is because you are likely to do multiple cases at once on the same die setting. The problem will continue with the next batch of cases if the die is not adjusted. They will not fire or they will misfire a lot. The bolt action will require that the extractor holds the case against the breech for a long time so that it fires. The case is driven forward, and the brass’s thinner portion expands, holding the chamber wall. The thicker part of case doesn’t expand and stretches back towards the bolt face. It will separate again if it doesn’t. It will separate the front part of the case from the chamber and pull the case head-off when it does. It then attempts to chamber the next round but gets stuck. This is often caused by range brass. You don’t know how many times it was fired/sized or in what firearm. It is best to keep it moving until you realize that the forward portion of the case must be removed. A quick tip: To remove the partial case, insert an oversized brush onto a cleaning rod and pull it backwards. When the bristles are pulled back, they act as barbs within the case. To prevent future problems, I would throw away any oversized cases that have been fired. If they haven’t been fired, there are some tricks that you can use to save them. A case gage would have been helpful again. Two: Double-check Your Primers. Another thing I see quite often is a high primer or backwards primer. Or no primer at all. High primers can cause a misfire or a slam-fire due to the firing pin seating the primer and using up its energy. To ensure that my rifle ammo works 100% of the time, I use a case gage to check it. Then, I put it in an ammunition box with the primer up. When the ammo is full, I run my finger through all the primers to check for any misalignments or backwards. Three: Check your Overall Cartridge Length. Trying to load the ammo in the shortest possible time can also cause problems. You should leave enough space between the tip and the magazine so that the rounds can feed 100%. Over the years, I’ve heard hunters get their rifle ready for hunting. They would load each shot individually and go to the range to sight-in. They discover that the magazine is too long for the ammunition to fit into the magazine when they reach the elk camp or deer camp. They have one shot at most, but it could be worse. I’ve seen hunters who had their buddies load the ammo for them, and then meet them at hunting camp to find that the ammo wouldn’t chamber due to the bullet being too long or the case being too small. Then they have a club. Four: Confirm that all cases contain powder. This doesn’t seem as common in rifle cartridges than in handgun cartridges. This could be due to handgun ammunition being loaded on progressive presses in greater quantities and more frequently. You may not realize how many rifle cartridges don’t contain powder. Because the pistol case has a smaller internal capacity, the bullet will stick to the barrel just enough to dislodge from it. A rifle has more internal capacity, and a better grip on your bullet because it has a smaller diameter and a longer bearing surface. A.223 case with no powder will not dislodge the bullet from the case. Instead, it will just get ejected from your rifle. This could be because the primer was wrong or something else. I load rifle cases on a single-stage press by placing them in a reloading blocks and always dumping my powder in a specific order. I then inspect the powder and pull the one that isn’t the same level as the rest. To check if there are any visuals inside, I inspect the first case. Then, I charge all three cases. If a case has powder hang up, just dump it in the next one. I use progressive presses to fill the case to the point where the bullet rests. This allows you to see the powder as the bullet rotates. If you have drained a double or partial charge, you will be able to tell as you seat the bullet. If I don’t load a progressive cartridge in one smooth stroke (say, a bullet was tipped over sideways and I raised it slightly to reset it), some presses actually back the charge back, adding more powder if it has already deposited some. This will give you a full charge plus a partial. If I can’t finish the procedure in one stroke, I pull out the case with powder inside it and either check the powder charge or dump the powder into the measure and run it through later.

Similar Posts: Tags : Ammo Inspection. Carroll Pilant. Cartridge Brass. Case Gage. Case Gauge. High Primer. OAL Check. Primers. Reloading. Sierra Bullets.