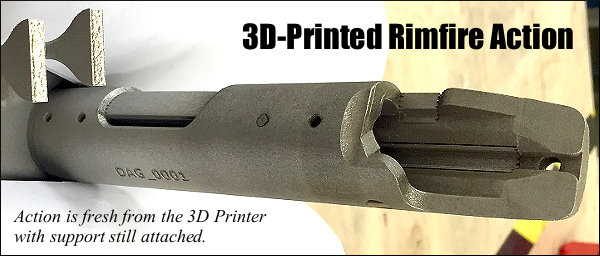

April 14, 2022. Here’s something really innovative — a 3D printed metal rimfire receiver! Forum member Marcos G. (aka MFP_BOP), has created and designed his own rimfire action. It’s not machined nor forged. This new action was created using a 3D sintered steel printer. Marcos is a 3D modeler by trade. He has access to a high-tech, but expensive, metal printer. Below is the actual recipient as printed. It has just been sent to be age-hardened up to 40 HRC. After that, final finishing work (e.g. Cleaning up tenon threads will be done. This FORUM Thread will provide more information about the 3D-printing project. When we think of 3D printing, most people think of small plastic parts. Nothing is as strong as steel. There are 3D printers that use sintered metal to create complex metal components. Marcus states that the receiver he created should have a yield and tensile strengths similar to investment casting. The action was made from 15-5 PH(R), Stainless Steel (in sintered). The action was designed for a PT&G 40X rimfirebol. Marcos points out that the action has an extraction cam that can be removed. This is something that would not be possible with regular machining or EDM. Marcos was born in Brazil and now resides in New Zealand. He told us that New Zealand is very gun-friendly. To become a receiver, I only need my ACAT license. There are no restrictions legal (as might be in the USA). The printer is an EOS270 laser metal-sintering machine. Marcos states that the current price of one of these machines is five figures. However, I am 99.99% certain that this technology will be available in the next five years. The receiver was 1.4 in diameter as it was designed. in diameter. Marcos reports that it was printed at 1.403?. The boltway design is.690? It came out at.687?. Marcos says: “I haven’t noticed any warping. The threads are really rough! The exterior and interior finishes look great, but it’s probably because the print was printed upside down (must have been tumbling after). To clean them up, I will need to run taps and single point-cut the Tenon threads. “Marcos claims that the actual printing process took a long time. “I should have asked how much it took to print!” Consider this: The 7-inch receiver is made in layers of 20 microns thick. This explains why it took so long to print.

Marcos 3D printed his own action to save money. Here’s some history… I tried several ways to get a Stiller 2500X into New Zealand. NZ $3000.00 was the final price. This is approximately $2195.00 USD. Although designing and making one would be cheaper, I felt that no one could machine the internal attachments with precision. Printing was a bit cheaper, and I could put in all the details I wanted, such as M4 threads and internal cams. “Similar Posts:Tags: 22LR, 3D, 3D Printing, 40X Bolt, Forum Thread, Marcos, Metal Printing, MFG_BOP, New Zealand, PT&G

Varmint Activities with AR-Platform Firearms in Saturday shows

Varmint Adventures with AR-Platform Rifles on April 19, 2025Saturday Movies: Varmint Season in some parts of the nation With flower quickly transitioning to summer. A semi-auto d weapons is a