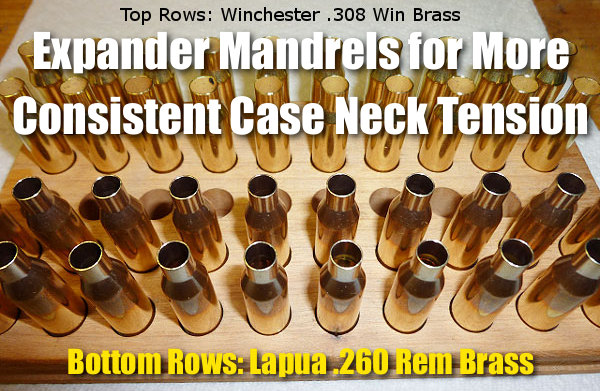

Before loading the new cartridge brass, run a mandrel expander down the case necks. This will smooth out dents and give a more uniform neck tension. Choose a diameter of mandrel that will provide the right neck tension. If you have a “no turn” chamber, you may be tempted to load and shoot. A minimal amount of case prep will help to ensure a more uniform neck tension. Maintaining a uniform neck tension allows for more consistent bullet seating. This, in turn, leads to better accuracy and a lower Extreme Spread (ES/SD). Lapua brass is tighter than optimal from the factory, especially 6mmBR, 6.×47, 6.5 Creedmoor and.308 win. You should at least inside chamfer the mouths of the cases after running an expander down the necks before you seat bullets. Both Sinclair Int’l’s (Brownells), and K&M’s expander mandrels will leave the necks with sufficient neck tension (more that.001”), so you can seat bullets without a second operation. We recommend putting some lube on the expander mandrel and running it down the necks. Remove any lube from the necks prior to seating bullets. Both Sinclair Tools and K&M Tools produce a die body that is specifically designed to hold expander-mandrels. Above is the Sinclair version. This $37.99 unit is designed to fit caliber-specific mandrels that measure approximately.001″ less than bullet diameter. This is a “Gen II” updated design that completely captures and locks the mandrel inside the die. It also has an O ring in the cap of the die that allows the mandrel self-centering within the case neck. Sinclair offers three sizes of expander mandrel die bodies:.17-.338 caliber (#749-011-715WS) $53.99;.357-.50 caliber ($37.99); and a special 50 BMG.50 Cal body (#749-019-163WS $51.99). All Generation II dies have been machined out of stainless steel. The standard diameter 7/8-14 dies come with the Sinclair Stainless Steel Split Lock Ring. After you have taken into account brass spring-back and run the Sinclair Expander Mandrel along the necks of Lapua Brass, you will have approximately.002″ neck tension*. This will improve the seating of bullets and remove any dents from the case mouths. Once the case mouths are all expanded, and uniformly round, then do your inside neck chamfering/deburring. The same expander mandrels are also useful for “necking up” smaller diameter brass or preparing brass for neck-turning. Mike Crawford, a forum member, adds: “These expansions can also reduce runout when offset seating is used. Expand the sized necks prior to bullet seating to force thickness variation outward. The necks will not be pushed out of the center with the Sinclair system. This will leave plenty of tension and the bullets will be seated more centrally. “I do this even with the necks turned to get better seating.”If you don’t have an expander mandrel, but DO have a full length sizing die that has an expander ball on it, this will work to “iron out the necks” and reduce tension. The necks will be more stressed if you use a die that has an expander ball. You first size the necks down, and then the ball expands the necks again. It is more common (but not always) for run-out to be worse when using an expansion ball instead of an expander mandrel. * This.002″ tension is what we’ve observed with Lapua 6mmBR brass, 6.5×47 brass, 6.5 Creedmoor brass, and.308 win. This may vary with smaller or larger cases. Also, different brands of brass will produce different results. If your current mandrel is too small, you can order a smaller diameter mandrel with 21st Century Innovation. They offer versions in stainless steel, Black Nitride or Titanium Nitride. The Nitride models are less frictional.

Gun Media at NRA Annual Meetings in GA — Live Broadcasts

April 21st, 2025The 2025 NRA Annual Meetings & Displays may have Tones of the Second Amendment. Popular internet visitors and listeners will transmit from a prominent “Radio Row ” at