June 5, 2022 Sunday Gunday: Multi-Tasking.308 Tubegun with Eliseo ChassisThis article showcases a stunning.308 Winchester tubgun, constructed with an Eliseo RTS chassis, Borden action and 30? Krieger medium Palma Contour barrel. Mark LaFevers, the owner, chambered and fitted his own barrel and assembled the rifle. Mark LaFevers also crafted the muzzle brake, front/rear bags-riders and his own “big-foot” bipod. Mark’s Do It-Yourself (DIY), tubegun has been as precise as it has been multi-faceted. This gun is optimized to shoot the 155-grain match projectiles. It’s a great tack-driver. The gun has been seen repeatedly putting 3-round groups in one hole at 100 yards by this Editor. The gun has been able to hold under 1 at 600 yards. The gun has held under 1? at 600 yards in competition. This rifle system is suitable for High Power (Palma), F-TR matches and Long Range Steel Matches. It can also be used in tactical competitions. Modern tubeguns can compete in 600-yard benchrest matches with the addition of a front sled. This was demonstrated by Jerry Tierney who won the NBRSA 600 yard Nationals with an Eliseo (Competition Machine).

The project started with a wishlist I created after participating in a precision tactical match in 2009. After that experience, I knew that I wanted a magazine fed precision bolt gun with a high-quality scope and variable-power scope. I wanted a rifle that could compete in a wide range of gun games, including tac comps and long distance prone events. The gun could also be used as a benchrest rig at medium range, which would meet the requirements of the monthly club matches that I shoot. These include a varmint-steel silhouette match (shot from the bench) and an F-Class style F-Class prone event. I also wanted a gun that could shoot Palma matches (when I learn to shoot with iron sights). Because I am interested in trying new shooting disciplines, I wanted to create a rifle that could be easily reconfigured to suit different needs. To maximize the gun’s potential, I used only the best-quality components for this project. I wanted to build as many rifles as possible myself, including fitting a barrel and chambering it. With so much to learn, I would rely heavily on the expertise and goodwill of others to ensure the gun’s success. The Do-It-Yourself Approach – The Appeal of Building Your Own Rifle

DIY (do it yourself) is not for everyone. Why would anyone attempt to make a rifle when they could hire professionals to do it? The potential savings can be a plus. A home gunsmith might find that it is more expensive to do it yourself, at least initially. Calculated. It’s not about saving money. It’s a great way to feel a sense of accomplishment when you build something yourself. It is important to me that you have a good understanding of craft, tools, materials, and practiced hands. Different people may have different definitions of DIY. It’s all about improvement. For me, it’s about a desire to improve and an appreciation for the importance of craftmanship throughout history. It’s also about trying to do my best. I felt a responsibility to maintain certain standards in this project. I was also motivated by the desire of paying homage to Daniel M. LeFever (a distant relative who made firearms in the 1870s). “Uncle Dan” LeFever made high-quality double guns that were comparable to the finest European doubles. *Choosing components for the.308 Win Tubegun

After looking through the selection of equipment available, Gary Eliseo’s Competition Machine tubgun chassis kit was discovered. Although initially attracted by the beautiful machine work in this aluminum stock’s aluminum stock, I found myself becoming more and more impressed with this platform. Gary’s RTS Kit for Remington 700 and Rem Clones accepts the well-known AICS magazines and allows stock adjustment flexibility. German Salazar’s excellent article on Configuring Eliseo Tubegun Stock explains more. I had seen the Borden action that our top Club benchrest record holder used, and it was something I could not miss. I was looking for a fully adjustable trigger group that could be adjusted for different pull weights in various shooting disciplines. Although Jewell seemed obvious, I was intrigued to see if there were other products that might be more suitable for my needs than the Jewell. Tom Myers, of X-Treme Shooting Products, suggested that an American-made trigger from CG Jackson might work. Tom’s company made a Mod 22 Tactical trigger with a fully adjustable, 2-stage Mod 22 Tactical stage that fits Remington 700 and their clones. It comes in a fixed or mobile shoe, with or with out a safety. I chose the fixed trigger shoe without safety.

A Nightforce scope was my first choice of optics after my positive experiences with Nightforce products. I had to choose between the NXS (side focus) and BR models and then chose a magnification range. I wanted to play a variety gun games, from Tactical to Benchrest. The NXS with its faster side-focus parallax adjustment seemed more versatile. I chose the 12-42x56mm version to have plenty of magnification for precision work long-range. You can dial it back to 12 power if you need a wider field.

Mark bench-testing this gun during Load Development. The superb SEB Neo Coaxial front rest is used.

Instead of focusing on the caliber options, I decided to take a step back and think about what I believed made winners shooters. Did it have to do with the caliber they were using or their skill, intelligence, and training that made them winners? Although each caliber has its own merits, it is equally true that a person with five times the training and skill as you will beat you with any caliber. One example is the tactical match that got me started with this project, won by a young Marine who shot a.308 Win. While there were many competitors with rifles with “faster and flatter, superior ballistics”, this Marine won the tactical match that got me started on this project. This was due to his superior training, natural abilities, and youthful edge. The.308 Win could still win this type of match with the right trigger puller. I had positive experience with the.308 Win and was ready to reload it. There are many bullets that have been proven to be reliable. F-TR and International Fullbore are two of the most popular disciplines. They allow.308 Win (7.62×51), as one of the permitted chamberings. Top shooters can provide guidance on load development and effective shooting techniques. The.308 Win barrel life is long. The.308 Win has a long barrel life.

You can narrow down the number of.308 bullet choices by choosing a bullet that has been successful for winning shooters and designing the gun around it. The bullet’s weight and preference for a particular seating depth determine the twist rate and chamber depth. This is dependent on whether you use single feed or magazine feed. Berger bullets have been very good to me, and Berger Ballistician Bryan Litz was very complimentary about the 155.5gr Palma bullet, so that was my first bullet choice for this gun. Bryan had great success at 1000 yards with a 1:13 twist barrel and the 155.5 bullet. I thought it would be interesting to see if he tried a 1:12 twist. twist. Krieger Barrels was capable of privde this particular twist rate. We hoped Krieger’s 5R rifle with a 30? A barrel of this length would be fast. A little extra velocity could offset any velocity loss that I might experience by being limited to a mag length COAL. (If I could load longer than the mag length, I could stuff more powder in and get more velocity. The Krieger 5R was a great choice. The barrel has been very easy to clean, it has been extremely accurate, and it holds very tight elevation at long distances. This Krieger has also allowed me to achieve very low ES/SD.

The rifle was first broken in at 100 yards at the Ojai Val Gun Club in California. Your Editor and me put through 40 rounds using Krieger’s recommended break in procedure. The barrel was ready to compete in less than 10 rounds, according to our impression. I spent the 10th round looking at the performance and design of the variable muzzle brake that I had made. The frosty 29 made it more obvious that there was a lot of gas being emitted from the gun, even though the baffle was only one. air. The front baffle spool was used to reduce recoil the most. After firing, the forward faces show a decreasing amount of powder residue from gas entry to exit. There is almost no residue at final baffle wall. This indicates that most of the gas has left to the side. Precision alignment shows that the brake has no effect on accuracy. The last 20 rounds were seated at various depths and yielded two three-shot, one hole groups of 100. The Krieger barrel was clean and easy to clean at the end of the session. Two wet patches were sufficient to remove the powder residue. A little copper was visible at the muzzle end after visual inspection. The Jim Borden action has a great feel when single-round loading and a consistent feed from the magazine. If the brass is not blocked from escaping, the ejector can be very aggressive and will throw it off the bench. The action is very smooth and the beautiful workmanship can be seen even though the tubegun chassis surrounds it.

Mark made two front sleds to go with the gun. One was made from metal and one was made from wood. This worked out a lot better. Mark says that the gun became stable with the wood bag-rider in position. This made it less noticeable that the gun’s high center of gravity. Mark also created his own rear Bag Rider. Tubegun wins first fun match

I broke in the barrel and took the gun to a nearby range to compete at a 300- and 400-yard paper contest. It would be fun to shoot loads in a fun match at club level. While I was getting the best grouping with 44.5 grains Varget, the hotter loads were not performing so well. This led me to believe that I would need to increase my loads from 44.0 to 44.5 by 10ths to find the sweet spot. I managed to win the 10-competitor match by 1 point. But a win is still a win. Load DevelopmentI took my rifle to the Ojai range at dawn to test load variations at 600 meters in 26? air. I printed targets (sourced from AccurateShooter.com’s FREE Target Page) that had a 1? I printed targets (sourced from AccurateShooter.com’s FREE Target Page) that had a 1? Grid box. At 600 yards, the dot was an excellent aim point. The Nightforce 12-42NXS optic’s capabilities were evident here. In the extremely clear conditions of the early morning, I was able to see both the dot and the bullet holes at 600 yards downrange. My 72-power Meade spottingscope was set up, but I didn’t use it because the Nightforce scope was more sharp and clear. The bullet holes on the targets were easily visible, so there was no need to go downrange. This is great because it allows me to make the most of the morning’s perfect air. I call this “Max Jam”, and press the bullet gently into the lands with a Hornady OAL gauge. The bullet will barely stick there when the tool is removed. [Editor’s note: Mark’s bullets were still in the lands at his optimal seating depth of.010. He is just shy of the maximum length he can load them with no set-back. The rounds can be loaded up to 2.850? OAL to magazine feed. Although I don’t cut a “no turn” chamber, I do light turning the outside of the case necks in order to uniformize them. I enjoy looking at bullet surface length variations using a Sinclair comparator and two.30-cal Inserts, one on each side of the bullet. This method is not intended to identify outlier bullets that are too long to separate from the group, as the Bergers bullets are uniform. This is not a knock on Berger, but a nod towards the manufacturing challenges of maintaining extremely tight tolerances. Today’s Varget five shot groups, jumping by tenths to 44.5 grains to 44.5 grains, revealed the best grouping to have been at 44.1 grains. Although the hotter loads were breaking 2900 fps, the groups were not as tight at the lower end. The five-shot Varget group had a vertical dispersion 1.9 at 44.1 grains. The horizontal dispersion was 1.25? At 600 yards, that makes it a keeper load.

As the NBRSA 600-yard match was fast approaching, I realized that I didn’t have enough Lapua brass in my arsenal to cover the match. I decided to use Hornady Match brass once again, which has also been a great choice. I packed up the best combinations of the Berger155.5s with Hornady/Varget and Lapua/Varget and Hornady/8208 to test them out at a 1000-yard range about two hours from my home. I expected to see Varget win at this distance, but I was surprised to see that the IMR 8208 performed almost identically. With this last minute perspective I decided to shoot the six target NBRSA match using Berger/Hornady/Varget for the first three matches, then Berger/Hornady/8208 for the last three matches when the extra speed might help in a rising afternoon wind.Match Results

Match 1 with 44.0 grains Varget was the best, pushing the Hornady Match brass Berger 155.5 to the limit. Although four bullets were able to reach a 1.44″ group in blue, it was a five-shot match. One bullet flew high left. Match 6 also showed great promise, with the IMR-8208 XBR powder delivering less than an inch vertical at 600 yards. The event taught me that operator consistency was more important than technical limitations of the ammunition or hardware. The gun can shoot much better than I can hold it. In this competition, I was able to shoot a beautiful SEB NEO frontrest. My Overall Impressions of the Project

The tubegun is a great choice for benchrest rigs. The pistol grip makes the gun more sensitive to steering errors than a standard low-profile benchrest stock. Consistency of grip is key. The gun responds well to a light grip and a firm cheek weld combination at the bench. However, the gun can also be fired in the prone position with a firm grip and heavy shoulder pressure. The Eliseo tubegun project is great and the final product is versatile and fun to shoot. To encourage others with similar interests, I will just say that this rifle is a great project and that my greatest challenge lies in my skill development, especially for tactical matches. You will need to have a new set of skills if you are only familiar with shooting matches at known distances. These UKD matches require a high level of shooting intelligence and training. I now have a rifle that inspires confidence and allows me to work on my skills. Overall, I am pleased with the results of this project. The gun certainly lives up to my expectations. It is robust, accurate, and extremely adept at multi-tasking. DIY Machining — Chambering My First Barrrel One of the main objectives of this project was to do my barrel chamber reaming, fit-up work. I had read John Hinnants’s excellent book Precision Rifle Barrel Making, built tools, and worked with the concepts so I felt ready to tackle the machining aspect of the project. Mac Tilton, a local gunsmith, was a great help in understanding what would be required. Greg Tannel’s excellent GreTan DVDs demonstrating how to set up a high-pressure thru-the-barrel flushing system and align your lathe tailstock correctly for precision chamber reaming were a great help. Greg’s flow control layout for flushing makes it easy to regulate the system for other purposes. The reamer holder Greg describes on his DVD was also built by me and works well. I started at the recommended starting point for everyone, which was to recheck my lathe’s level, a Jet 1340 belt-driven model with a Jet 1340 gearhead. I used a precise 12″ Grizzly Tools machinist tool to accomplish this. The leveling process is tedious and time-consuming, so I can’t claim that it was easy to use. However, the level worked well. Dave Manson shares his Reamer knowledge

When researching which reamer manufacturer to use to make the custom reamer to fit the Berger 155.5 fullbore rifle bullet, I found that it seemed to like about.015? Jump to the lands. I was attracted to Dave Manson’s products by my name recognition. After years of reading through Brownells catalogs, I was impressed by the amount of thought Dave had put into the creation of many of his tools. Dave’s knowledge of chamber tolerances, cutting fluids, and reamer modifications for thru-the-barrel flushing was invaluable to me. We had several phone conversations. To help me spec the reamer, Dave received a few dummy rounds that were magazine-length to help him make a custom reamer that would yield a.015″ jump as well as a no turn neck. I was quickly able to use the Dave Manson reamer for practice with the flushing system using pieces from a take off barrel. Then, I checked dimensions using Cerrosafe casts. The dimensions were exactly what we had discussed. I knew that this tool would make a better chamber from the way Dave’s reamer worked inside practice chambers. Chambering Process with Tailstock DRO

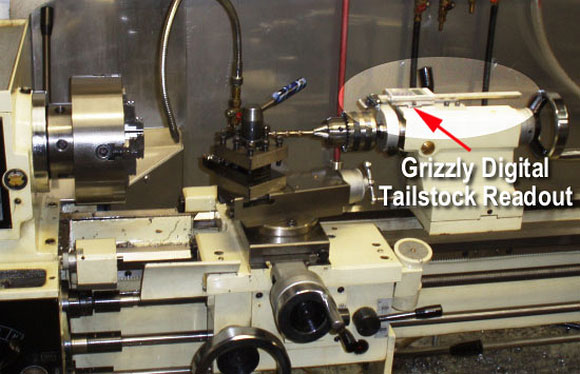

To keep track of boring depth, I set up a digital readout for the lathe tailstock from Grizzly (part # T10118). The DRO allows you to see the total travel distance on a digital display. This is a far better alternative to counting the revolutions of the tailstock handlewheel. The stainless Krieger barrel was used to cut the chamber at 60 RPM. Mobilmet 744 heavy-cutting oil was diluted with mineral spirits and flushed the reamer flutes at 100 PSI. The lathe power was turned off for the final few thousandths of the cut. The cut was completed by turning the reamer holders by hand and in-feeding the lathe tailstock handlewheel with the lathe tailstock. This allows for precise chamber dimension control and depth control. To shorten this article up a bit and keep it on point for those interested in the rifle and not the process, let me just mention that details of some of the additional parts I made can be seen at my website: LaFeversFabricating.wordpress.com. These parts include my muzzle brake, my fast attach bipod design and a drop-leg height. I also made wooden grip and metal front and rear bag riders to support benchrest work. Acknowledgements

I want to thank them for their patience and support of this project. Also, for their patience with my many questions about parts or processes, I would like you to list them alphabetically:Berger Bullets — Bergerbullets.com — Berger 155.5gr Fullbore Match Bullets.

Jim Borden — BordenRifles.com — Stainless Rem. Clone action for Eliseo tubegun.

Gary Eliseo — CompetitionShootingStuff.com — RTS tubegun stock kit.

Grizzly Industrial — Grizzly.com

Krieger Barrels — KriegerBarrels.com — 30? Medium Palma, 1:12.5? Twist 5R rifling, tight bore.

Dave Manson — MansonReamers.com — Custom .308 Win finish reamer for Berger 155.5 fullbore bullet.

Tom Myers — XtremeShooting XTSP – CG Jackson Mod 22 Tactical 2Stage Trigger.

Nightforce Optics — NightforceOptics.com – 12-42×56 NXS Scope and NP-R1 Ranger.

Greg Tannel — GreTanRifles.com – Lathe setup and chambering DVDs. Chuck Hawks says that “Uncle Dan Lefever was one the most important gun designers of his time, or any time.” He started several companies …. The most well-known, Lefever Arms Co. was acquired by the Ithaca Gun Company during the First World War. There were many guns in the golden age of the American double, with many grades and prices. These guns ranged from simple field guns to exquisite masterpieces that rivaled the finest European guns. At an International Arms Exhibition, the Lefever Arms guns won medals for ‘Best American’ or ‘World’s Best’ shotguns.

Similar Posts