January 16th 2022Sunday gunday: Remington 700 — History X-Ray, Blueprinting. Today’s Sunday GunDay story is about the Remington 700, the iconic American bolt-action rifle. We begin by covering the history and evolution of the Rem 700 rifle. Then we show you the Rem 700 through a series cutaway animations. We then explain how gunsmiths can enhance Remington 700 actions through “blueprinting”. After World War II, Remington Arms engineer Mike Walker developed lower-cost alternatives for the Model 30. This led to the Model 721. These receivers were made from cylindrical bar stock and could be turned on a lathe rather than being machined in a series or milling operations. This greatly reduced production costs. Walker continued to develop the basic 721 action and produced the Model 722, Model 725 and, finally, the Model 700 in 1962. Walker sought to improve the accuracy of the rifles by using tight tolerances in chamber and bore, a fast leade and a fast lock time. The Remington 700 action, like the 721, was intended for mass production. Remington produced two versions of the Model 700, the ADL (long-action) and the BDL (short-action). Remington made improvements to the rifle in 1969. These included a longer rear bolt shroud and a jeweled bolt. Four years later, Remington began producing left-handed Rem 700s to compete with the Savage Model 110. The Model 700 was not only a hunting rifle but also served as the basis for police and military sniper rifles. In 1966, the U.S. Marine Corps ordered the M40 rifle. In 1986, the U.S. Army adopted M24 Sniper Weapon System.

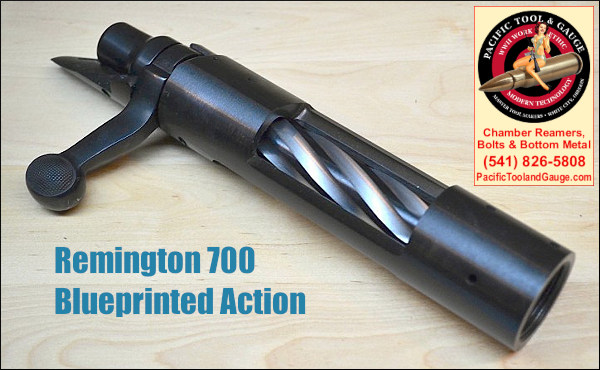

Both short- and long-action Remington 700s are available. This photo is taken from the Big ED YouTube Video comparing the two action lengths. The bolt face is recessed and fully covers the base of cartridge. The extractor is a C clip that is located within the bolt face. The coil spring actuates the ejector, which is a plunger that sits on the bolt face. The bolt is made of three pieces, which are brazed together (head and body) The receiver is made from round cross-sectional steel. Many companies have developed after-market chassis systems in response to the popularity of Remington 700 series rifles and the availability Rem 700 barreled action by themselves. This GunMan YouTube Video examines five modern chassis systems for Remington 700 barreled action rifles. Modular chassis systems are very popular with PRS/NRL competitors. This GunMan YouTube Video shows five modern chassis systems for Remington 700 barreled actions. 3D computer graphics make it possible. Modern software can allow detailed side-views with “cutaway” (see below), and 3D views with 360? rotation. As you can see, the software can also offer X-Ray-type views of the gun’s internals. Computer animations can also show the entire firing process, from trigger pull to chambering the next round. This Rem 700 animation is truly amazing! This video is a must-see for any bolt-action shooter. Remington Arms has been manufacturing the Model 700 series bolt-action rifles since 1962. They all share the same centerfire bolt action. They come with an internal magazine, depending on the caliber. Some have a floor plate for quick-unloading. Others are blind (no floor-plate). The Remington 700 is a modification of the Remington 721 series of rifles. It has “Cock On Opening”, which means that the bolt rotates upwardly when the rifle is opened. This cocks the firingpin. Cam mechanism moves the firing pin’s firing pin’s cocking part backwards. The cartridge’s base is enclosed by the bolt face, which is fully recessed. The C-clip that is located within the bolt face houses the extractor. The coil spring actuates the ejector, which is a plunger that sits on the bolt face. The bolt is made of three pieces, which are brazed together (head and body). The bolt handle is also available. The receiver is made from round cross-sectional steel. What operations are performed to an action during blueprinting? Bill Marr, a gunsmith from RifleShooter.com, has written a helpful article that will help you understand the blueprinting process for Rem 700. This article demonstrates how manual tools can be used to complete the tasks. Bill, who owns 782 Custom Gunworks Ltd. can perform many of these operations using modern automated machinery. Bill has written a follow up article on Truing Rem 700 receivers with a Lathe. Bill’s informative article explains how he blueprints the Remington 700 short-action receiver with a.308 Win bolt. He walks through the steps of action disassembly.

Ream Minor Diameter Receiver Threads

Square the Receiver Lugs

Square the Face of the Recipient

Lap the Bolt Lugs

Square the Bolt FaceBill used a variety Brownells tools to complete the blueprinting job. These included: Remington 700 Armorer’s Kit; Manson Receiver Accurizing kit; Bolt Lapping Tool; Bolt Face Truing tool; Manson Receiver Ring Facing Cut; Multi-Vise Jaw Pads; SiliconeCarbide Abrasive; Do-Drill cutting oil. Truing the Receiver’s FaceUsing the receiver facing instrument, the receiver’s front is verified. The tool is placed on top of the tap and rotated by hand. To lubricate the tool, we used Do Drill. Lapping the LugsThe bolt lap tool is a device that screws into the front end of the action and applies rearward pressure to the bolt face. A small amount of lapping compound should be applied to the front of each lug. The bolt handle can then be raised and lowered several times. It is important that no lapping compound is applied to any other surfaces. Truing the Bolt FaceOn the bolt, the central portion of the bolt face was lower. This Rem 700 bolt face is now perfectly square to the action after the truing operation. Important: Rifleshooter.com states that this article highlights our project and is provided for information purposes only. This article provides a brief overview of the process, but it should not be attempted without the supervision and guidance of an experienced gunsmith. If you are interested in a Blueprinted Remington 700 action but don’t have a good gunsmith near you (or don’t want to wait for many weeks), Pacific Tool & Gauge can help you order one starting at $637.99 (see below).

Similar Posts:Tags to: Bill Marr Blueprinting Action Rem 700 Chassis System Remington 700 Remington 700 Rifleshooter.com