It’s a good practice to extend the cut just below the neck-shoulder intersection when neck-turning the cases. This will help keep the neck tension uniform after repeated firings by preventing brass buildup where the neck meets shoulder. Craig, an Irish member of our Forum who calls himself a “neck-turning beginner”, had some trouble turning brass for 20 tactical cases. He was correct in attempting to cut slightly beyond the neck-shoulder intersection, but was concerned that the brass was being removed from the shoulder too far.

Craig writes: “Everywhere that I’ve read about neck-turning, [it] says you need to cut a little into the neck/shoulder intersection to stop doughnutting. I understand this, but I can’t get my neck-turning set-up to touch the neck/shoulder intersection. It either doesn’t cut [the shoulder] at all or cuts the shoulder almost completely, which looks messy. It doesn’t matter how I adjust the neck-cutting mandrel, it either cuts too much or not enough. It may be related to the bevel of the cutter on my neck-turning device …”

We can all agree that Craig didn’t have to cut into the shoulder so deeply. This situation can be solved easily. Craig uses a neck-turning device with a relatively shallow cutter bevel. This 20-degree angle has been set up to work with any shoulder angle. As you move the cutter down the neck a shallow angled tip will remove brass quite far down. You should only extend the cut by about 1/32 inch beyond the neck-shoulder intersection. This will eliminate the brass buildup at the neck base that can cause the formation of doughnuts.

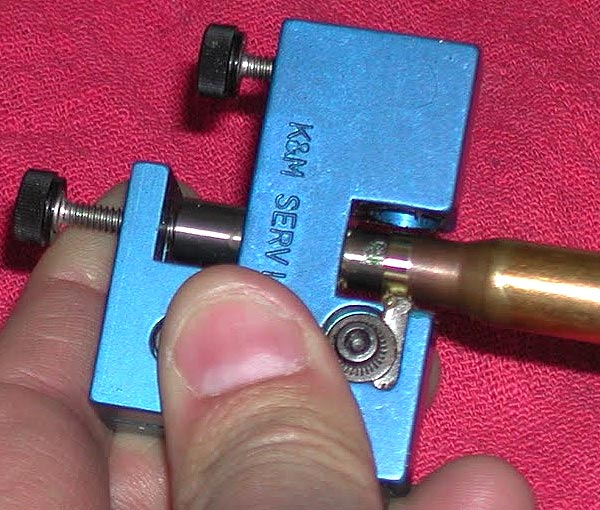

Use a cutter tip that has a wider angle, say 30 to 40 degrees. The K&M neck-turning tools (above) have a shorter bevel which is better suited to a shoulder with a 30deg angle. Also available is a 40deg point. PMA Tool and 21st Century Shooting offer carbide cutters in a variety bevel angles that will match your case’s shoulder angle*. WalkerTexasRanger says: “I switched to a 40 degree cutter head to solve this issue and I am much happier with the result.” Sinclair Int’l sells the 40-degree heads for about $15. Forum member CBonner agrees: “I had the exact same problem with my NT-series tools. The 40-degree Cutter was the solution.” Below is Sinclair’s NT-series Neck-Turning Tool 40deg Cutter. This 40deg Cutter, item NT3140 costs $14.99. Sinclair also offers the 30deg Cutter item NT3100 for the same price.

Al Nyhus offers another clever solution. “The best thing I’ve found is to get an additional shell holder, face it off by.020-.025 then run the cases through the sizing tool. This will move the shoulder.020-.025. You then turn your neck down to the new’ neck/shoulder intersection and stop there. By seating the bullets deeply into the lands, you can fireform the cases and blow the shoulder forward. The extra neck length that you gained by setting the shoulder back will now blend perfectly into the shoulder. The result is a case that fits the chamber perfectly and has zero donuts.”

* 21st Century offers carbide cutters at 15, 17, 20, 23, 28, 30, 35, forty, 46, and fifty degrees. PMA Tool offers carbide cutters for: 15 BMG (also known as BMG), 17, 20, 21, 25, 28, 30, 30 Shortneck (30 degrees), 35, 40 and 45 degrees.